Binder Content

一、 Overview

Asphalt binder content affects HMA mixture performance in the areas of stiffness, strength, durability, fatigue life, raveling, rutting and moisture damage. Therefore, it is important in HMA quality assurance, pavement forensic investigations and HMA research.

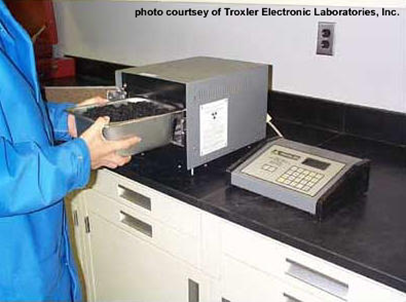

The ignition test is the most common method used to determine HMA asphalt binder content. In the ignition method the HMA is heated in an oven (Figure 121) sufficiently to burn the asphalt binder within the mixture. The difference in weight before and after burning in the ignition oven gives a measure of asphalt binder content. The remaining aggregate can also be analyzed for gradation.

The standard ignition test procedure is found in:

- AASHTO T 308 and ASTM D 6307: Determining the Asphalt Binder Content of Hot-Mix Asphalt (HMA) by the Ignition Method

Figure 121: Maximum theoretical specific gravity sample.

Figure 121: Maximum theoretical specific gravity sample.

二、 Background

Quantitative determination of the asphalt binder content of HMA mixtures and pavement samples is necessary for many reasons, including: quality control, specification acceptance, and mixture evaluation studies. HMA that has too much asphalt binder can experience problems such as bleeding, lowered skid resistance, and lowered resistance to permanent deformation (rutting and shoving). HMA that has too little asphalt binder can have lowered fatigue resistance and problems with raveling and stripping.

Methods of Determination

There are several methods used to determine HMA asphalt binder content. Solvent extraction methods are used to separate then remove the constituent asphalt binder from the aggregate. The before and after masses are then compared to determine asphalt binder content. These methods also produce aggregate on which a gradation test can be performed. The nuclear method uses a nuclear source and detector to determine the asphalt binder content.

Ignition Method

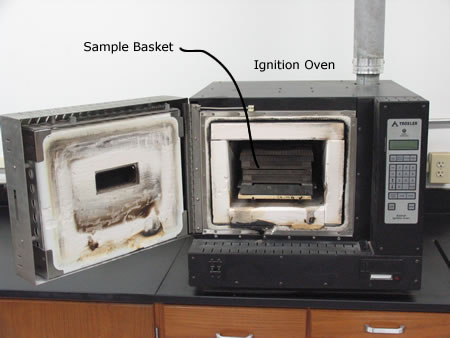

he ignition method of determining asphalt binder content allows for the asphalt binder in an HMA sample to be burned off in an oven (Figure 122) at temperatures above the flame point of the binder. Asphalt binder content is then calculated by subtracting the mass of the aggregate remaining after the asphalt binder is burned off from the initial mass of the test sample. This method eliminates the need for the chlorinated solvents used in solvent extraction methods.

Originally, a 1969 study by Antrim and Busching suggested that asphalt binder content of HMA samples could be determined by an “ignition method” that involved the virtual complete combustion of asphalt binder at a high temperature. Studies at the National Center for Asphalt Technology (NCAT) in the early 1990s followed up on this idea and improved on the equipment and methods. Today, the ignition test is the most common method for determining HMA asphalt binder content and gradation.

Figure 122: Ignition oven with door open.

Figure 122: Ignition oven with door open.

Correction Factor

Antrim and Busching (1969[1]) noticed that during the asphalt binder burning process, some aggregate lost mass. Therefore, the difference in mass before and after the burning reflected not only the asphalt binder content but a small amount of aggregate mass. If the aggregate mass loss was not accounted for, the ignition method would tend to over predict asphalt binder content. This aggregate mass loss is likely due to:

- A small fraction of aggregate actually burning off or losing weight with the asphalt binder.

- Aggregate abrasion during HMA mixing. Aggregate with lower abrasion values tends to show more mass loss in the ignition method. This is likely due to the creation of more fines due to aggregate abrasion during the mixing process.

In order to account for aggregate mass loss, a correction factor is applied to the results in order to obtain the best estimate of asphalt binder content. This correction factor is typically between 0 and 0.5 and is generally higher for more abrasion susceptible aggregates like limestone.

Accuracy and Reliability

Tests at NCAT (Brown et al., 1995[2]) show that the accuracy, precision and reliability of this test method is at least as good as extraction methods.

Solvent Extraction Methods

Solvent extraction methods (described in AASHTO T 164 and ASTM D 2172) use a solvent to remove asphalt binder from aggregate in an HMA mixture. Asphalt binder content is then calculated by subtracting the mass of the aggregate remaining after the asphalt binder is removed from the initial mass of the test sample. These methods have been used reliably for many years but their use of chlorinated solvents create disposal problems.

Typically, removal of the asphalt binder is accomplished by submerging a loose HMA sample in one of several approved solvents (trichloroethylene, 1,1,1-trichloroethane or methylene chloride are typical) for a period of time to let the solvent disintegrate the sample. After this, the solvent mixture is separated from the remaining aggregate using a variety of techniques, centrifuge separation (Figure 123 and Figure 124) being quite popular.

Figure 123: Uncovered centrifuge used in a solvent extraction

method.

Figure 123: Uncovered centrifuge used in a solvent extraction

method.

Figure 124: Centrifuges for use in the solvent extraction method.

Figure 124: Centrifuges for use in the solvent extraction method.

Nuclear Asphalt Content (NAC) Gauge

A nuclear asphalt content (NAC) gauge (Figure 125) uses a neutron source, such as Americium-241:Beryllium, placed inside the gauge. The source emits high energy, “fast” neutrons, which then collide with various nuclei in the sample. Due to momentum conservation, those neutrons that collide with hydrogen nuclei slow down much quicker than those that collide with other, larger nuclei. The gauge detector counts only thermal (low energy) or “slow” neutrons thereby making the detector count proportional to the number of hydrogen atoms in the pavement. Since asphalt binder contains many hydrogen atoms, the detector count is proportional to asphalt content. A calibration factor is used to relate thermal neutron count to actual moisture content. Note that water (H2O) also contains hydrogen atoms and will affect NAC measurements. Additionally, NAC gauges cannot directly measure gradation since they do not separate the asphalt binder and aggregate. Usually, a solvent is used to separate the aggregate for gradation measurement.

Figure 125: Nuclear asphalt content gauge.

Figure 125: Nuclear asphalt content gauge.

三、 Test Description

The following description is a brief summary of the test. It is not a complete procedure and should not be used to perform the test. The complete test procedure can be found in:

- AASHTO T 308 and ASTM D 6307: Determining the Asphalt Binder Content of Hot Mix Asphalt (HMA) by the Ignition Method

Summary

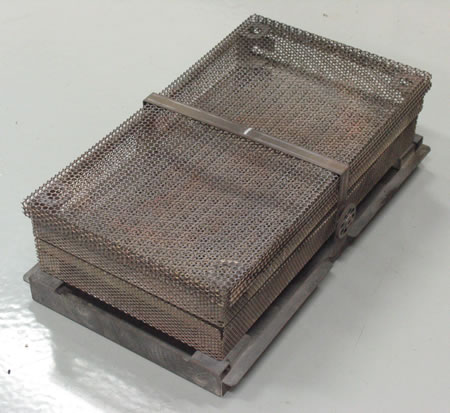

A loose HMA sample is spread out in a mesh basket and placed in a forced air furnace. The furnace heats the HMA and burns off the asphalt binder component (called “ignition”). Comparing the HMA sample weight before ignition and the aggregate weight after ignition gives the weight of asphalt binder burned off during ignition. A correction factor is needed to account for aggregate mass loss during ignition. Figure 126 shows the major test equipment.

Figure 126: Ignition method major equipment

Figure 126: Ignition method major equipment

Approximate Test Time

Approximately 1 hour.

Basic Procedure

- 1. Obtain a sample of loose HMA produced in the laboratory or plant.

- 2. Quarter the sample to obtain the required amount of HMA (Figure 127). The size of the test sample is determined by the nominal maximum aggregate size as shown in Table 16. If necessary, the sample may be heated in an oven at 257°F (125°C) until it is workable.

- Table 16: Sample Mass Requirements

- 3. Determine a correction factor for the aggregate in the mix. The correction factor accounts for aggregate breakdown during the burning process.

- ○ Prepare 2 calibration samples at the design asphalt binder content.

- ○ Test samples in the ignition oven and determine their asphalt binder contents as measured in the ignition oven.

- ○ Perform a gradation analysis on the residual aggregate and compare this gradation with the control sample to evaluate the amount of aggregate degradation.

- ○ Determine the difference between the asphalt binder content as prepared and as measured in the 2 samples. The calibration factor is the average of these differences.

- ○ If the calibration factor is greater than 0.5 percent, lower the test temperature to 900°F (482°C) and perform the calibration procedure again.

- Preheat the ignition oven to the desired temperature, typically 1000°F ( 538°C).

- Dry the HMA sample in an oven at 221°F (105°C) until it reaches a constant mass or determine the sample’s moisture content.

- Enter the HMA’s correction factor determined in step 3 into the ignition oven controller.

- Weigh the empty sample baskets and catch pan (with sample guards in place).

- Distribute the sample evenly in the sample basket (Figure 128) and level with a spatula or trowel.

- 9. Weigh the sample, basket, and catch pan together.

- 10. Calculate the initial mass of the sample by subtracting the mass obtained in step 7 from the mass obtained in step 9. Input this amount into the ignition oven controller.

- 11. Place the sample basket into the oven (Figure 129), close the door, and initiate the test by pressing the “start” button.

- 12. Allow the sample to burn until the change in mass of the sample does not exceed 0.01 percent for three consecutive minutes. Most ovens calculate this automatically and notify the user with a light and audible indicator. This can also be done manually by periodically removing the sample from the oven, waiting for it to cool and then weighing it. The first removal is at 45 minutes, while subsequent removals are at a minimum of 15 minute intervals.

- 13. Record the corrected asphalt binder content in percent from the ticket printed from the oven (ticket usually resembles a cash register receipt).

- 14. Remove the sample from the oven and allow it to cool to room temperature.

Figure 127: Preparing a sample for quartering.

Figure 127: Preparing a sample for quartering.

| Nominal Maximum Aggregate Size | Minimum Sample Mass, g | |

|---|---|---|

| U.S. | Metric | |

| 1.5 inches | 37.5 mm | 4000 |

| 1.0 inches | 25.0 mm | 3000 |

| 0.75 inches | 19.0 mm | 2000 |

| 0.5 inches | 12.5 mm | 1500 |

| .375 inches | 9.5 mm | 1200 |

| No. 4 | 4.75 mm | 1200 |

IA correction factor must be determined for each mix type before any testing in the ignition oven is completed (AASHTO, 2000b).

Figure 128: Assembled sample basket.

Figure 128: Assembled sample basket.

Figure 129: Inserting the sample into the hot ignition oven.

Figure 129: Inserting the sample into the hot ignition oven.

Results

Parameters Measured

Asphalt binder content of the HMA sample. A gradation test can also be run on the remaining aggregate.

Specifications

There are no specifications directly associated with the asphalt binder content test. Specifications are usually associated with the job mix formula (JMF) asphalt binder content and a tolerance band around i

Typical Values

See typical values for asphalt binder content.

Calculations (Interactive Equation)

Calculate the corrected asphalt binder content using the following equation:

Where:

- Pb = asphalt binder content (percent)

- WS = HMA sample weight before ignition

- WA = aggregate weight after ignition

- CF = correction factor (percent)

If the ignition oven provides a printed ticket, it should be attached to the report. It