Moisture Susceptibility

Moisture susceptibility is a primary cause of distress in HMA pavements. HMA should not degrade substantially from moisture penetration into the mix. HMA mixtures may be considered susceptible to moisture if the internal asphalt binder-to-aggregate bond weakens in the presence of water. This weakening, if severe enough, can result in stripping (Figure 147).

To measure the potential for moisture damage to HMA mixtures, moisture susceptibility testing can be performed. Results from the moisture susceptibility test may be used to predict the potential for long-term stripping and to evaluate anti-stripping additives, which are added to the asphalt binder, aggregate, or HMA mixture to help prevent stripping.

Figure 147: Fatigue cracking caused by stripping.

Figure 147: Fatigue cracking caused by stripping.

一、 Background

Moisture damage is the result of moisture interaction with the asphalt binder-aggregate adhesion within a HMA mixture. This interaction can cause a reduction of adhesion between the asphalt binder and aggregate (Figure 148 and Figure 149), called stripping, which can lead to various forms of HMA pavement distress including rutting and fatigue cracking.

Over the years, many different tests have been used to evaluate a particular HMA mixture’s susceptibility to moisture damage. These tests range from simple (e.g., the boiling test) to the more complex (e.g., Hamburg wheel tracking test). The moisture susceptibility test specified by Superpave mix design is typically called the modified Lottman test. This test is described in the Test Description section. This section, taken largely from Hicks (1991[1]) describes the actual moisture damage mechanism, factors influencing moisture damage, preventative measures and alternative tests.

Figure 148: HMA samples with no moisture damage (left) and moisture damage

(right). Notice the amount of uncoated aggregate on the damaged sample.

Figure 148: HMA samples with no moisture damage (left) and moisture damage

(right). Notice the amount of uncoated aggregate on the damaged sample.

Figure 149: HMA samples with no moisture damage (left) and moisture damage

(right). A more subtle example than Figure 2, but still with noticeable uncoated

aggregate.

Figure 149: HMA samples with no moisture damage (left) and moisture damage

(right). A more subtle example than Figure 2, but still with noticeable uncoated

aggregate.

Asphalt Binder and Aggregate Adhesion

Moisture damage is the reduction in adhesion between the asphalt binder and aggregate surface in an HMA mixture. In order to understand its causes and preventive measures, a brief discussion of adhesion mechanisms is presented here. There are 4 principal means of asphalt binder-aggregate adhesion:

- Mechanical. Asphalt binder gets into the surface irregularities and pores of the aggregate and hardens causing a mechanical lock. Moisture on the aggregate can interfere with asphalt binder penetration into the aggregate and decrease the mechanical lock, thus increasing susceptibility to stripping.

- Chemical. A chemical reaction between the asphalt binder and aggregate surface occurs causing chemical adhesion. In general, aggregates with acidic surfaces do not react as strongly with asphalt binders. This weaker reaction may not be strong enough to counter other moisture damage factors.

- Adhesion tension. The tension between the asphalt binder and aggregate at the wetting line (as a drop spreads over a surface, the edge of the drop is the “wetting line”) is generally less than the tension between water and aggregate. Therefore, if all three are in contact, water will tend to displace asphalt binder. This can result in poor wetting of the aggregate surface by the asphalt binder and lead to stripping. This interfacial tension between asphalt binder and aggregate varies with asphalt binder type, aggregate type and aggregate surface roughness.

- Molecular orientation. When in contact with aggregate, asphalt molecules tend to orient themselves in relation to the ions on the aggregate surface essentially creating a weak attraction between the asphalt binder and aggregate surface. If water molecules, which are dipolar, are more polar than asphalt binder molecules, they may preferentially satisfy the energy demands of the aggregate surface. The resulting weak asphalt binder-aggregate bond can result in stripping.

Factors Influencing Moisture Damage

Moisture susceptibility is a complex phenomenon dependent upon the previously discussed mechanisms. The nature of these mechanisms and their interaction makes it difficult to predict with certainty whether a particular characteristic will be the overriding factor in determining moisture susceptibility. In general, moisture susceptibility is increased by any factor that increases moisture content in the HMA, decreases the adhesion of asphalt binder to the aggregate surface or physically scours the asphalt binder. Each of the factors listed below influence moisture susceptibility to some degree but no single one is a foolproof benchmark for predicting moisture susceptibility.

- Asphalt binder characteristics. Viscosity is important because it may indicate higher concentrations of asphaltenes (large polar molecules). Polar molecules can create greater adhesion tension and molecular orientation adhesion. Therefore, lower viscosities, which may represent lower concentrations of asphaltenes, are generally more susceptible to stripping. Individual components in asphalt binder such as sulfoxides, carboxylic acids, phenols and nitrogen bases can also affect stripping potential.

- ○ Aggregate characteristics (Figure 4). In general, aggregates that are hydrophilic (attract water) are more likely to strip than aggregates that are hydrophobic (repulse water). To address this, either stripping-susceptible aggregates can be avoided or an anti-stripping asphalt binder modifier can be used. The key aggregate properties that determine this hydrophilic/hydrophobic characteristic are:

- Surface chemistry. Surfaces that can more readily form bonds with the asphalt binder are less likely to cause stripping. In general, a more acidic aggregate surface is more susceptible to stripping. Iron, magnesium, calcium and perhaps aluminum are considered beneficial, while sodium and potassium are considered detrimental (Hicks, 1991[1]).

- Porosity and pore size. Pore size is the critical factor. If pores are large enough to allow asphalt binder entry, they may be a contributor to moisture susceptibility. High porosity results in high absorption, which means that more asphalt binder must be used to achieve the desired effective asphalt binder content. Conversely, if high porosity is not considered, for a given amount of asphalt binder, more will be absorbed and less will be available to create the asphalt binder film around aggregate particles causing faster aging and possibly stripping.

- Air voids. The extent to which pores in the aggregate absorb asphalt binder affects the volume of air voids in the HMA mixture. When HMA air voids exceed about 8 percent by volume, they may become interconnected and allow water to easily penetrate the HMA and cause moisture damage through pore pressure or ice expansion. To address this, HMA mix design adjusts asphalt binder content and aggregate gradation to produce design air voids of about 4 percent. Excessive air voids can be either a mix design or a construction problem and this section only addresses the mix design problem.

- Construction weather. Cool weather construction can lead to insufficient compaction, resulting in high air voids and a relatively permeable HMA pavement. This increases the likelihood of water in the pavement structure and thus, moisture damage. Wet weather can also increase the moisture content in the constructed HMA.

- Climate. Wetter climates, freeze-thaw cycles and temperature fluctuations can all allow more moisture into the HMA structure thus increasing the likelihood of moisture damage.

- Traffic. If water is present in the HMA structure, increased traffic loading can accelerate moisture damage for 2 reasons:

- Pore pressure buildup. If water is in the aggregate pores and cannot escape, traffic loading will tend to compress these pores and cause a pressure buildup, which could push asphalt binder away from the aggregate surface.

- Hydraulic scouring. Wheel passes over a HMA pavement tend to move water in the pavement. This movement causes a scouring action that could remove asphalt binder from the aggregate surface.

Preventive Measures

Various measures can be taken to prevent, or at least minimize, moisture damage. These measures range from material selection, to construction practice, pavement design and HMA additives:

- Aggregate selection. Choose low porosity aggregate with rough, clean surfaces.

- Prevent moisture penetration into the HMA pavement. Reduce the permeability of the pavement structure by manipulating air void content, lift thickness and gradation (Figure 5 and Figure 6). Additionally, surface treatments such as fog seals, slurry seals or bituminous surface treatments (BSTs) can essentially waterproof the HMA surface.

- Pretreat aggregate. Modify aggregate surface properties to replace ions that are likely to contribute to poor asphalt binder-aggregate adhesion.

- Anti-strip additives. Add chemicals or lime to the asphalt binder or HMA to prevent moisture damage (Figure 150).

- ○ Chemicals. Generally work to reduce surface tension in the asphalt binder, which promotes better wetting, as well as impart an electrical charge to the asphalt binder that is opposite that of the aggregate surface charge. Most chemical additives contain amines and are added at about 0.1 to 1.0 percent by weight of asphalt binder. Chemical additives are generally added to asphalt binder prior to mixing with aggregate but this can cause some waste as not all the additive is guaranteed to reach the critical asphalt binder-aggregate interface. Some additives can be added to the aggregate before mixing with asphalt binder so that all the additive is on the aggregate surface.

- ○ Lime (Figure 151) . Works by replacing negative ions on an aggregate surface with positive calcium ions, resulting in better asphalt binder-aggregate adhesion. Also reacts with molecules in both the asphalt binder (carboxylic acid) and aggregate (acidic OH groups) that results in molecules that are more readily absorbed on the aggregate surface or molecules that are less likely to be dissociate and associate with water molecules. Lime is usually added at about 1.0 to 1.5 percent by total aggregate weight. Moisture is needed to activate the lime, so lime is usually added as a slurry or added to slightly moist aggregate.

Figure 150: Aggregate on left has severe stripping., right has 0.5

percent by weight asphalt binder antistripping modifier.

Figure 150: Aggregate on left has severe stripping., right has 0.5

percent by weight asphalt binder antistripping modifier.

Figure 151: Lime in small containers for addition during mix design

sample preparation.

Figure 151: Lime in small containers for addition during mix design

sample preparation.

Moisture Susceptibility Tests

In general, moisture susceptibility tests do not measure individual factors but rather attempt to quantify a HMA mixture’s ability to resist moisture damage, no matter what the source. They are typically capable of providing gross results or comparative results and are not able to predict the degree of moisture damage. A brief description of the major tests for moisture susceptibility follows:

- Boiling test (ASTM D 3625). Add loose HMA to boiling water and measure the percentage of total visible area of aggregate surface that retains its asphalt binder coating. The test is simple but is subjective, does not involve any strength determination and examining the fine aggregate is difficult.

- ../../../static-immersion test (AASHTO T 182). HMA sample is immersed in water for 16 to 18 hours and then observed through the water to measure the percentage of total visible area of aggregate surface that retains its asphalt binder coating. This test is also simple but subjective and does not involve any strength determination.

- Lottman test. Tests 3 sets of compacted samples. Group 1, the control group, is not conditioned. Group 2, representing field performance at 4 years, is subjected to vacuum saturation with water. Group 3, representing field performance at 4 to 12 years, is subjected to vacuum saturation and a freeze-thaw cycle. A split tensile test is performed on each sample and the ratio of the indirect tensile strength of the conditioned samples is compared to the control group as a ratio. A minimum tensile strength ratio (TSR) of 0.70 to 0.80 is often used as a standard.

- Tunnicliff and Root conditioning. Similar to the Lottman test, this test uses only 2 groups and eliminates the freeze-thaw group.

- Modified Lottman (AASHTO T 283). A combination of the Lottman and Tunnicliff and Root tests. It compares the split tensile strength of unconditioned samples to samples partially saturated with water. The test subjects the conditioned group to partial vacuum saturation and an optional freeze-thaw cycle. Although it is expected that the water conditioned samples will have a lower tensile strength, excessively low values indicate the potential for moisture damage.

- Immersion-compression (AASHTO T 165). Similar to a modified Lottman test, but the conditioned samples are only placed in water (not vacuum saturated) and an unconfined compressive strength test is used instead of the split tensile test. Precision is not good and samples showing obvious signs of stripping can give a strength ratio of near 1.0.

- Hamburg wheel-tracking device. Compacted HMA samples are tested underwater. Results give a relative indication of moisture susceptibility.

All of these tests have weaknesses that result in an ongoing search for a better moisture susceptibility test. These weaknesses, in addition to the ones discussed above, tend to be issues with repeatability and reproducibility of test results and questionable predictive ability. Also, small variations in key HMA parameters such as air voids (Va), can substantially affect test results.

二、 Test Description

The following description is a brief summary of the test. It is not a complete procedure and should not be used to perform the test. The complete test procedure can be found in:

- AASHTO T 283: Resistance of Compacted Bituminous Mixture to Moisture-Induced Damage

- ASTM D 4867: Effect of Moisture on Asphalt Concrete Paving Mixtures

Summary

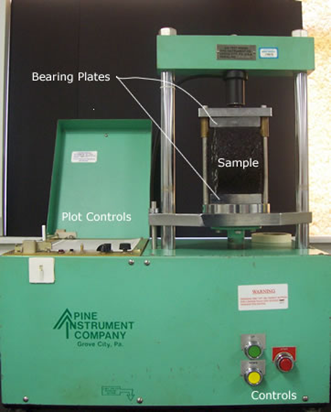

Two sets of HMA samples are subjected to a split tensile test (often called an indirect tensile” test). One set is conditioned by partial vacuum saturation with water, soaking in water for 24 hours and an optional freeze-thaw cycle. The other set is used as a control. The ratio of the average split tensile strength of the conditioned samples over the average split tensile strength of the unconditioned (control) samples is reported as the tensile strength ratio (TSR). Figure 152 shows the split tensile test setup.

Figure 152: Split tensile test setup.

Figure 152: Split tensile test setup.

Approximate Test Time

The total test time can be up to 6 days. Major components are:

- Up to 4 days of sample preparation

- 16 hours for the freeze cycle

- 24 hours for the thaw cycle

- 2 hours for getting samples to test temperature

- 30 minutes to run conditioned and unconditioned sample sets through the indirect tensile test

Basic Procedure

- 1. Prepare 6 HMA samples. Samples are usually 6 inches (150 mm) in diameter and 4 inches (100 mm) thick. After mixing has occurred, allow the HMA to cool to room temperature for 2 hours.

- 2. Cure the HMA in an oven at 140°F (60°C) for 16 hours.

- 3. After curing, place HMA in an oven at 275°F (135°C) for two hours before compaction.

- 4. Compact mix to 7 percent air voids, or a void level expected in the field, using the SGC, California kneading compactor or Marshall hammer.

- 5. Store the compacted samples at room temperature for 72 to 96 hours.

- 6. Determine the theoretical maximum specific gravity (Gmm), bulk specific gravity (Gmb), height, volume and air void content (Va) of each sample.

- 7. Divide the six samples into two subsets of three. The average air void content (Va) for each subset should be similar. One subset will be “unconditioned” (tested in a dry state) and the other will be “conditioned” (tested in a saturated state).

- 8. Unconditioned samples. While the conditioned samples are being conditioned, the unconditioned samples sit at room temperature.

- Wrap samples in plastic or put them in a heavy duty leak proof bag.

- Store samples at room temperature until testing.

- 9. Conditioned samples. These samples are saturated with water to between 55 and 80 percent using the following procedure:

- Place each sample in a vacuum container supported above the container bottom by a spacer and fill the container with water until the sample is covered by 1 inch (25 mm) of water.

- Apply a vacuum of 10 – 26 inches Hg partial pressure (13 – 67 kPa absolute pressure) for 5 to 10 minutes (Figure 153).

- Remove the vacuum and let the sample sit under water for another 5 to 10 minutes.

- Calculate bulk specific gravity (Gmb) and compare the SSD mass with the SSD mass obtained in step 6 to determine the volume of absorbed water.

- Determine degree of saturation by comparing volume of absorbed water with volume of air voids (Va) obtained in step 6.

- Moisture condition the samples by placing them in a bath of distilled water at 140°F (60°C) for 24 hours (Figure 154). If the samples were freeze-thaw conditioned, remove the plastic from the samples as soon as possible after placement in the bath.

- 10. Place samples in a 77 °F (25 °C) water bath for a minimum of 2 hours (Figure 155).

- 11. Run an indirect tension test on each sample by placing the sample between the two bearing plates (Figure 156) in the testing machine and applying the load at a constant rate of 2 inches/minute (50 mm/minute) (Video 1).

- 12. Record the tensile strength values and calculate and report the tensile strength values.

Samples of other sizes may be used. If aggregate larger than 1 inch (25 mm) is present in the HMA, a larger sample size should be used.

Figure 153: Vacuum saturation of a sample.

Figure 153: Vacuum saturation of a sample.

If the calculated saturation of a sample is below 55 percent, repeat the saturation procedure. If the calculated saturation of a sample is above 80 percent, the sample is considered damaged and must be discarded.

If freeze-thaw conditioning is desired, wrap each sample in plastic and place it in a plastic bag containing 0.6 in3 (10 mL) of water. Seal the bag and place it in a freezer at 0°F (-18°C) for at least 16 hours.

Figure 154: Moisture conditioning bath.

Figure 154: Moisture conditioning bath.

Figure 155: Filling the 2-hour room temperature water bath.

Figure 155: Filling the 2-hour room temperature water bath.

Make sure the load is applied along the diameter of the sample.

Figure 156: Sample placed between the bearing plates before

testing.

Figure 156: Sample placed between the bearing plates before

testing.

Video 1: Indirect tension test

三、 Results

Parameters Measured

The ultimate parameter to be measured is the tensile strength ratio (TSR). However, in order to get this measurement the following other parameters need to be measured:

- Theoretical maximum specific gravity (Gmm) of each sample

- Bulk specific gravity (Gmb) of each sample

- Air void content (Va) of each sample

- Percent saturation of the conditioned samples

Specifications

Table 17: Superpave Mix Design Moisture Susceptibility Specification

| Material | Value | Specification | HMA Distress of Concern |

|---|---|---|---|

| HMA | Tensile strength ratio | ≥ 0.80 | Moisture damage,stripping |

Typical Values

Typical TSR values range from 0.70 to 0.90. Depending on the type of HMA mixture, it is not uncommon to see values below 0.70 or above 0.90.

Calculations (Interactive Equation)

Calculate the tensile strength as follows:

Where:

- St = tensile strength (psi)

- P = maximum load (lbs)

- t = sample thickness (inches)

- D = sample diameter (inches)

Express the resistance to moisture damage as a ratio of the unconditioned sample tensile strength that is retained after the conditioning.

Calculate the TSR as follows:

Where:

- TSR = tensile strength ratio

- S1 = average tensile strength of unconditioned samples

- S2 = average tensile strength of conditioned samples