Coarse Aggregate Specific Gravity

一、 Overview

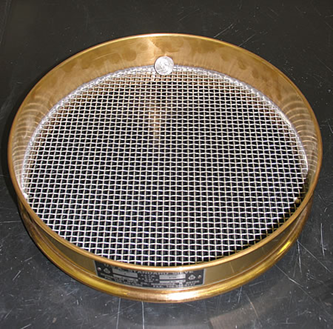

The coarse aggregate specific gravity test (Figure 71) is used to calculate the specific gravity of a coarse aggregate sample by determining the ratio of the weight of a given volume of aggregate to the weight of an equal volume of water. It is similar in nature to the fine aggregate specific gravity test.

Figure 71: Coarse Aggregate Specific Gravity (CASG).

Figure 71: Coarse Aggregate Specific Gravity (CASG).

The coarse aggregate specific gravity test measures coarse aggregate weight under three different sample conditions:

- Oven-dry (no water in sample).

- Saturated surface-dry (SSD, water fills the aggregate pores).

- Submerged in water (underwater).

- AASHTO T 85 and ASTM C 127: Specific Gravity and Absorption of Coarse Aggregate

Using these three weights and their relationships, a sample’s apparent specific gravity, bulk specific gravity and bulk SSD specific gravity as well as absorption can be calculated.

Aggregate specific gravity is needed to determine weight-to-volume relationships and to calculate various volume-related quantities such as voids in mineral aggregate (VMA), and voids filled by asphalt (VFA). Absorption can be used as an indicator of aggregate durability as well as the volume of asphalt binder it is likely to absorb.

The standard coarse aggregate specific gravity and absorption test is:

二、 Background

Specific gravity is a measure of a material’s density (mass per unit volume) as compared to the density of water at 73.4°F (23°C). Therefore, by definition, water at a temperature of 73.4°F (23°C) has a specific gravity of 1.

Absorption, which is also determined by the same test procedure, is a measure of the amount of water that an aggregate can absorb into its pore structure. Pores that absorb water are also referred to as “water permeable voids”.

Specific Gravity Use

Aggregate specific gravity is used in a number of applications including Superpave mix design, deleterious particle indentification and separation, and material property change identification.

Superpave Mix Design

Superpave mix design is a volumetric process; it relies on mixing constituent materials on the basis of their volume. However, aggregate and asphalt binder volumes are diffucult to measure directly, therefore a material’s weight is typically measured and then converted to a volume based on its specific gravity. Correct and accurate material specific gravity determinations are vital to proper mix design. An incorrect specific gravity value will result in incorrect calculated volumes and ultimately result in an incorrect mix design.

Material Contamination Indicator and Separator

Specific gravity can also indicate possible material contamination. For instance, deleterious particles (Figure 2) are often lighter than aggregate particles and therefore, a large amount of deleterious material in an aggregate sample may result in an abnormally low specific gravity.

Material Change Indicator

Finally, specific gravity differences can be used to indicate a possible material change. A change in aggregate mineral or physical properties can result in a change in specific gravity. For instance, if a quarry operation constantly monitors the specific gravity of its output aggregate, a change in specific gravity beyond that normally expected could indicate the quarrying has moved into a new rock formation with significantly different mineral or physical properties.

Aggergate Absorption Use

Aggregate absorption is the increase in mass due to water in the pores of the material. Aggregate absorption is a useful quality because:

- 1. High values can indicate non-durable aggregate.

- 2. Absorption can indicate the amount of asphalt binder the aggregate will absorb.

It is generally desirable to avoid highly absorptive aggregate in HMA. This is because asphalt binder that is absorbed by the aggregate is not available to coat the aggregate particle surface and is therefore not available for bonding. Therefore, highly absorptive aggregates (often specified as over 5 percent absorption) require more asphalt binder to develop the same film thickness as less absorptive aggregates making the resulting HMA more expensive.

Aggregate Specific Gravity Types

Several different types of specific gravity are commonly used depending upon how the volume of water permeable voids (or pores) within the aggregate are addressed (Figure 3):

- Apparent Specific Gravity, Gsa. The volume measurement only includes the volume of the aggregate particle; it does not include the volume of any water permeable voids. The mass measurement only includes the aggregate particle. Apparent specific gravity is intended to only measure the specific gravity of the solid volume, therefore it will be the highest of the aggregate specific gravities. It is formally defined as the ratio of the mass of a unit volume of the impermeable portion of aggregate (does not include the permeable pores in aggregate) to the mass of an equal volume of gas-free distilled water at the stated temperature.

- Bulk Specific Gravity (Bulk Dry Specific Gravity), Gsb. The volume measurement includes the overall volume of the aggregate particle as well as the volume of the water permeable voids. The mass measurement only includes the aggregate particle. Since it includes the water permeable void volume, bulk specific gravity will be less than apparent specific gravity. It is formally defined as the ratio of the mass of a unit volume of aggregate, including the water permeable voids, at a stated temperature to the mass of an equal volume of gas-free distilled water at the stated temperature.

- Bulk Saturated Surface Dry (SSD) Specific Gravity. Volume measurement includes the overall volume of the aggregate particle as well as the volume of the water permeable voids. The mass measurement includes the aggregate particle as well as the water within the water permeable voids. It is formally defined as the ratio of the mass of a unit volume of aggregate, including the weight of water within the voids filled to the extent achieved by submerging in water for approximately 15 hours, to the mass of an equal volume of gas-free distilled water at the stated temperature.

- Effective Specific Gravity, Gse. Volume measurement includes the volume of the aggregate particle plus the void volume that becomes filled with water during the test soak period minus the volume of the voids that absorb asphalt. Effective specific gravity lies between apparent and bulk specific gravity. It is formally defined as the ratio of the mass in air of a unit volume of a permeable material (excluding voids permeable to asphalt) at a stated temperature to the mass in air (of equal density) of an equal volume of gas-free distilled water at a stated temperature. Effective specific gravity is determined by a different procedure and is not covered in this section.

Relationship with Other Specific Gravities

Refer to Figure 4 for abbreviations.

- The difference between Gsa and Gsb is the volume of aggregate used in the calculations. The difference between these volumes is the volume of absorbed water in the aggregate’s permeable voids. Both use the aggregate’s oven dry weight.

- The difference between Gsb and bulk (SSD) specific gravity is the weight of aggregate used in the calculations. The difference between these weights is the weight of absorbed water in the aggregate’s permeable voids. Both use the same aggregate volume.

- The difference between Gsa, Gse and Gsb is the volume of aggregate used in the calculations. All three use the aggregate’s oven dry weight.

- The following relationships are always true:

- 1. Gsa ≥ Gse ≥ Gsb

- 2. Bulk (SSD) specific gravity ≥ Gsb

- 3. Aggregate specific gravities (Gsb, Gsa,Gse and bulk SSD specific gravity ) are all ≥ Gmm(because Gmm includes the asphalt binder, which has a lower specific gravity than the aggregate)

三、 Test Description

The following description is a brief summary of the test. It is not a complete procedure and should not be used to perform the test. The complete procedure can be found in:

- AASHTO T 85 and ASTM C 127: Specific Gravity and Absorption of Coarse Aggregate

Summary

The mass of a coarse aggregate sample is determine in SSD, oven-dry and submerged states. These values are then used to calculate bulk specific gravity, bulk SSD specific gravity, apparent specific gravity and absorption. Figure 72 shows major coarse aggregate specific gravity equipment.

Figure 72: Major CASG equipment.

Figure 72: Major CASG equipment.

Approximate Test Time

3 days (from sample preparation to final dry weight determination)

Basic Procedure

- 1. Obtain a sample of coarse aggregate material retained on the No. 4 (4.75 mm) sieve (Figure 73). This sample size is based on nominal maximum aggregate size (NMAS). Sample sizes range from 2000 g for a 0.5 inch (12.5 mm) NMAS to 5000 g for a 1.5 inch (37.5 mm) NMAS.

- 2. Prepare the material.

- Wash the aggregate retained on the No. 4 (4.75 mm) sieve. This discards small aggregate particles clinging to the retained large particles.

- Dry the material until it maintains a constant mass. This indicates that all the water has left the sample. Drying should occur in an oven regulated at 230°F (110°C).

- Cool the aggregate to a comfortable handling temperature.

- Immerse the aggregate in water at room temperature for a period of 15 to 19 hours (Figure 74).

- 3. Dry the sample to a saturated suface dry (SSD) condition. Rolling up the aggregate into the towel and then shaking and rolling the aggregate from side to side is usually effective in reducing the sample to a SSD condition (Video 12). It may be necessary to wipe the larger particles separately. Once there are no visible signs of water film on the aggregate particle surfaces, determine the sample mass.

- 4. Place the entire sample in a basket (Figure 75) and weigh it underwater (Figure 76). The basket should be pre-conditioned to the water bath temperature. Shake the container to release any entrapped air before weighing. The container overflow needs to work properly to compensate for the water displaced by the sample.

- 5. Remove the aggregate from the water and dry it until it maintains a constant mass. This indicates that all the water has left the sample. Drying should occur in an oven regulated at 230°F (110°C).

- 6. Cool the aggregate in air at room temperature for 1 to 3 hours then determine the mass.

Figure 73: No. 4 (4.75 mm) sieve.

Figure 73: No. 4 (4.75 mm) sieve.

Figure 74: Soaking the sample.

Figure 74: Soaking the sample.

If the aggregate is not oven-dried before soaking, specific gravity values may be significantly higher. This is because in the normal procedure the water may not be able to penetrate the pores to the center of the aggregate particle during the soaking time. If the aggregate is not oven-dry to start, the existing water in the aggregate pore structrure may be able to penetrate further into the pores (AASHTO, 2000c[1]).

Make sure to use cloth and not paper towels. Paper towels may absorb water in the aggregate pores.

Figure 75: The basket used for underwater weighing.

Figure 75: The basket used for underwater weighing.

Figure 76: Weighing the sample underwater

Figure 76: Weighing the sample underwater

四、 Results

Parameters Measured

- 1. Coarse aggregate bulk specific gravity.

- 2. Coarse aggregate bulk SSD specific gravity.

- 3. Coarse aggregate apparent specific gravity.

- 4. Coarse aggregate absorption.

Specifications

There are no minimum or maximum specific gravity or absorption values in Superpave mix design. Rather, specific gravity is an aggregate quality needed to make required volume calculations. Some state agencies specify minimum aggregate specific gravities or maximum percent water absorption to help control aggregate quality.

Typical Values

Specific gravities can vary widely depending upon aggregate type. Some lightweight shales (not used in HMA production) can have specific gravities near 1.050, while other aggregate can have specific gravities above 3.000. Typically, aggregate used in HMA production will have a bulk specific gravity between about 2.400 and 3.000 with 2.700 being fairly typical of limestone. Bulk SSD specific gravities can be on the order of 0.050 to 0.100 higher than bulk oven dry specific gravities, while apparent specific gravities can be 0.050 to 0.100 higher still./p>

For a particular aggregate type or source, fine aggregate specific gravities can be slightly higher than coarse aggregate specific gravities because as the aggregate particles get smaller, the fraction of pores exposed to the aggregate surface (and thus excluded from the specific gravity calculation because they are water-permeable) increases./p>

Aggregate absorption can also vary widely depending upon aggregate type. Some lightweight shales (not used in HMA production) can have absorptions approaching 30 percent, while other aggregate types can have near zero absorption. Typically, aggregate used in HMA production will have an absorption between just above zero and 5 percent. Absorptions above about 5 percent tend to make HMA mixtures uneconomical because extra asphalt binder is required to account for the high aggregate absorption./p>

If absorption is incorrectly accounted for, the resulting HMA could be overly dry and have low durability (absorption calculated lower than it actually is) or over-asphalted and susceptible to distortion and rutting (absorption calculated higher than it actually is)./p>

Calculations

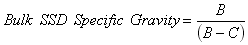

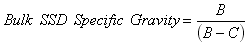

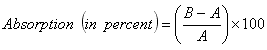

Three different masses are recorded during the test. Their common symbols are:

A = mass of oven-dry sample in air (g)

B = mass of SSD sample in air (g)

C = mass of SSD sample in water (g)

These masses are used to calculate the various specific gravities and absorption using the following equations:

Note that the quantity (B – C) is the mass of water displaced by the SSD aggregate sample. In the apparent specific gravity calculation the mass of the SSD aggregate sample is replaced by the mass of the oven-dry aggregate sample (A replaces B), which means that the water permeable voids within the aggregate are not included and (A – C) is the mass of water displaced by the oven-dry sample.

The ratios given in the equations are then simply the ratio of the weight of a given volume of aggregate to the weight of an equal volume of water, which is specific gravity.

Certainly, the accuracy of all measurements is important. However, of specific concern is the mass of the SSD sample. The determination of SSD conditions can be difficult. If the sample is actually still wet on the surface then the mass of the SSD sample will be higher than it ought to be, which will cause a lower calculated bulk specific gravity. Conversely, if the sample is beyond SSD and some of the pore water has evaporated (which is more likely), the mass of the SSD sample will be lower than it ought to be, which will cause a higher calculated bulk specific gravity. Either type of error will have a cascading effect on volumetric parameters in other tests that require specific gravity as an input and Superpave mix design.

A quick check of the results should show that bulk specific gravity is the lowest specific gravity, bulk SSD specific gravity is in the middle and apparent specific gravity is the highest.