Aggregate Tests

Sulfate Soundness Test

The soundness test determines an aggregate’s resistance to disintegration by weathering and, in particular, freeze-thaw cycles.

read more ...Fine Aggregate Specific Gravity

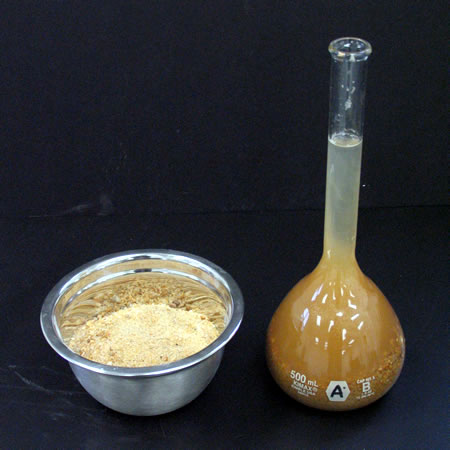

The fine aggregate specific gravity test (Figure 1) is used to calculate the specific gravity of a fine aggregate sample by determining the ratio of the weight of a given volume of aggregate to the weight of an equal volume of water. It is similar in nature to the coarse aggregate specific gravity test.

read more ...Triaxial Test

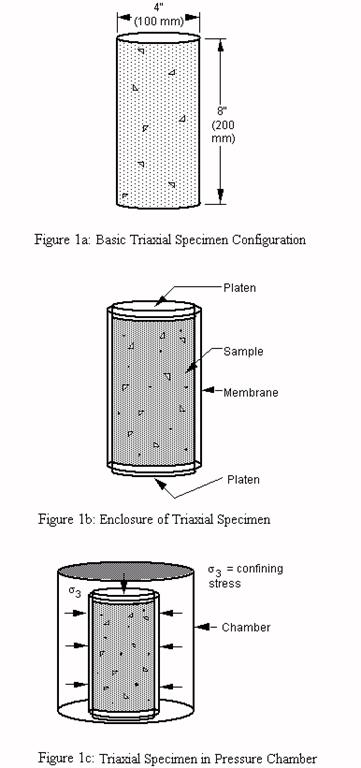

In a triaxial resilient modulus test a repeated axial cyclic stress of fixed magnitude, load duration and cyclic duration is applied to a cylindrical test specimen. While the specimen is subjected to this dynamic cyclic stress, it is also subjected to a ../../../static confining stress provided by a triaxial pressure chamber. The total resilient (recoverable) axial deformation response of the specimen is measured and used to calculate the resilient modulus using the following equation:

read more ...Gradation Test

The gradation and size test (Figure 1) is used to determine aggregate particle size distribution. Size distribution is perhaps the single most important aggregate quality associated with the control of HMA mixtures. Aggregate gradation and size affect HMA volumetric properties as well as mixture permeability and workability.

read more ...Fineness Modulus

For aggregates used in PCC, another common gradation description for fine aggregate is the fineness modulus. It is described in ASTM C 125 and is a single number used to describe a gradation curve. It is defined as:

read more ...Particle Index

Description The particle index test provides a combined shape-texture characterization. This test requires that an aggregate sample be divided up into specific size fraction. Each size fraction is placed into a container in three layers. This is done twice; the first time, each layer is compacted with 10 blows of a tamping rod, and the second time, each layer is compacted with 50 blows of a tamping rod. The particle index is computed from the following equation:

read more ...Fine Aggregate Angularity

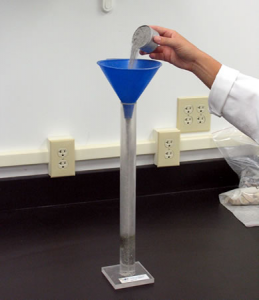

Overview The fine aggregate angularity (FAA) test (Figure 25) is an indirect method of assessing the angularity of fine aggregate. Fine aggregate angularity is important because an excess of rounded fine aggregate (often in the form of natural sand) can lead to HMA rutting.

read more ...Flat and Elongated Particles

Overview The flat and elongated particle test is used to determine the dimensional ratios for aggregate particles of specific sieve sizes. This characterization is used in the Superpave specification to identify aggregate that may have a tendency to impede compaction or have difficulty meeting VMA specifications due to aggregate degradation. Flat or elongated particles (Figure 36) tend to lock up more readily (rather than reorient) during compaction making compaction more difficult. They also have a tendency to fracture during compaction along their weak, narrow dimension, which can effectively make aggregate gradation finer and possibly cause lower-than-expected

read more ...Percent Fractured Face Test

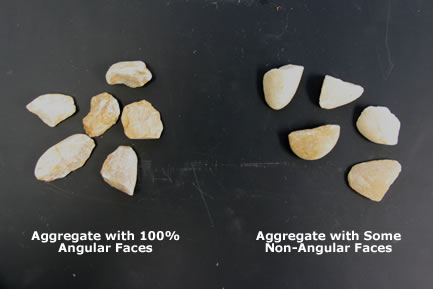

A sample retained on the 4.75 mm (No. 4) sieve is collected and the number of particles with fractured faces is compared to the number of particles without fractured faces. A fractured face is defined as an “angular, rough, or broken surface of an aggregate particle created by crushing, by other artificial means, or by nature” (ASTM, 2000[1]). In order for a face to be considered fractured it must constitute at least 25 percent of the maximum cross-sectional area of the rock particle.

read more ...Los Angeles Abrasion

Overview The Los Angeles (L.A.) abrasion test (Figure 43) is a common test method used to indicate aggregate toughness and abrasion characteristics. Aggregate abrasion characteristics are important because the constituent aggregate in HMA must resist crushing, degradation and disintegration in order to produce a high quality HMA.

read more ...Sand Equivalent

Overview The sand equivalent test (Figure 58) is a rapid field test to show the relative proportions of fine dust or clay-like materials in fine aggregate (or granular soils). The term “sand equivalent” expresses the concept that most fine aggregates are mixtures of desirable coarse particles (e.g., sand) and generally undesirable clay or plastic fines and dust (ASTM, 2003[1]).These materials can coat aggregate particles and prevent proper asphalt binder-aggregate bonding.

read more ...Coarse Aggregate Angularity

Overview The coarse aggregate angularity (CAA) test is a method of determining the angularity of coarse aggregate (Figure 64). Coarse aggregate angularity is important to ensure adequate aggregate interlock and prevent excessive HMA deformation under load (rutting).

read more ...Coarse Aggregate Specific Gravity

Overview The coarse aggregate specific gravity test (Figure 71) is used to calculate the specific gravity of a coarse aggregate sample by determining the ratio of the weight of a given volume of aggregate to the weight of an equal volume of water. It is similar in nature to the fine aggregate specific gravity test.

read more ...Sieve

A sieve is a mechanical device used to separate samples of different sizes.Sieve sizes typically used for Superpave mix design are 1½ in, 1.0 in, ¾ in, ½ in, 3/8 in, No. 4, No. 8, No. 16, No. 30, No. 50, No. 100 and No. 200 (37.5, 25.0, 19.0, 12.5, 9.5, 4.75, 2.36, 1.18, 0.600, 0.300, 0.150 and 0.075 mm) sieves. Assemble the sieves in order of decreasing size of opening from top to bottom and place the nest of sieves over a pan (Video 13).

read more ...