Fine Aggregate Angularity

Figure 25: Fine aggregate angularity test.

Figure 25: Fine aggregate angularity test.

The FAA test estimates fine aggregate angularity by measuring the loose uncompacted void content of a fine aggregate sample. On a sample of known gradation, the loose uncompacted void content is indicative of the relative angularity and surface texture of the sample. The higher the void content, the higher the assumed angularity and rougher the surface.

This test is used to ensure that the blend of fine aggregate has sufficient angularity and texture to resist permanent deformation (rutting) for a given traffic level.

The standard fine aggregate angularity test is:

- AASHTO T 304 or ASTM C 1252: Uncompacted Void Content of Fine Aggregate

一、 Background

The FAA test indirectly measures the angularity of fine aggregate using the aggregate’s uncompacted void content. Angularity is a description of the degree of roughness, surface irregularities or sharp angles of the aggregate particles (Figure 26). Angular particles do not compact as readily as rounded particles because their angular surfaces tend to lock up with one another and resist compaction, while smoother, more rounded surfaces tend to pass by one another allowing for easier compaction. Therefore, the higher the measured uncompacted void content, the more angular the material.

Figure 26: More angular (left) vs. more rounded (right) fine aggregate.

Figure 26: More angular (left) vs. more rounded (right) fine aggregate.

Angular materials are desirable in paving mixtures because they tend to lock together and resist deformation after initial compaction, whereas rounded materials may not produce sufficient inter-particle friction to prevent rutting. The measured uncompacted voids are affected by the shape, angularity and texture of the fine aggregate, the aggregate grading and specific gravity.

FAA can indicate the effect of the fine aggregate portion of the mixture on the overall properties of the mixture. It is generally believed that low FAA values will result in an unstable HMA mixture (e.g., potential for rutting and shoving) and high FAA values will result in a stable HMA mixture if all other mixture properties are satisfactory.

The National Aggregates Association (NAA) developed the original test upon which the FAA test is based. The FAA test has been adopted as a Superpave consensus aggregate requirement.

FAA Methods

There are three methods used for finding void content. Methods A and B are generally specified when trying to compare the angularity of different fine aggregate sources to remove the effect of gradation. Superpave specifies Method A to determine FAA. Research has shown that the results for various materials tested by Method A and B are highly correlated.

Method A

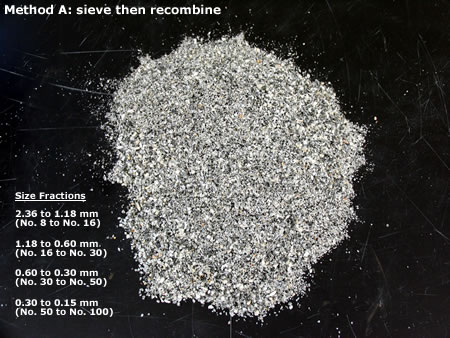

This method uses a sample of a specified gradation that is obtained by combining individual sieve size fractions from a typical fine aggregate sieve analysis (Figure 27). Method A is most useful as a quick test to indicate the particle shape, angularity and texture properties of a fine graded sample. Method A results are relatively independent of actual as-obtained gradation because the particles are first sieved and then recombined in a precise gradation.

Figure 27: Method A

Figure 27: Method A

Method B

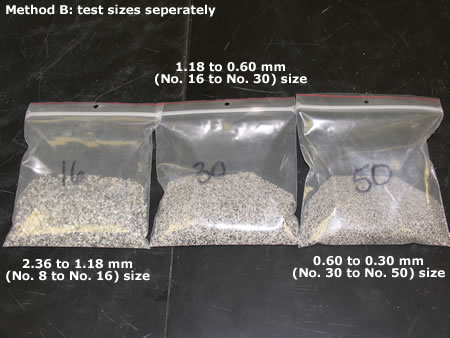

This method uses each of three fine aggregate size factions. Each size is tested separately (Figure 28). Method B is more time consuming and requires a larger initial sample, but provides additional information concerning the shape and texture characteristics of individual sizes. Method B will give higher void contents than method A or C because it is dealing with uniformly graded samples and thus, there are no aggregate particles of smaller sizes to fill in the voids between the uniformly sized particles.

Figure 28: Method B.

Figure 28: Method B.

Method C

This method measures the uncompacted void content of the minus No. 4 (4.75 mm) portion of the as received material (Figure 29). With method C, the measured void content depends not only on particle shape and texture, but gradation as well.

Figure 29: Method C.

Figure 29: Method C.

Current FAA Issues

It has been found through research that the FAA test method does not consistently identify angular, cubical aggregates as high quality materials (Chowdhury et al., 2001[1]). The basic test assumption is that more fractured faces will result in higher void content in the loosely compacted sample; therefore a specification on air void content is a good proxy for much more difficult-to-measure specifications on fine aggregate fractured faces and shape. This assumption is not always true. Cubical shaped particles with 100 percent fractured faces (highly desirable characteristics) may not meet the FAA requirement of 45 for high-volume traffic. In some areas of the U.S. it can be difficult to meet this requirement with local aggregate sources (Haddock, 2000[2]). Chowdhury et al. (2001[1]) recommend a reduction of the high-volume traffic specification to 43.

Alternate FAA Tests

Because of the above issues, alternate methods to characterize fine aggregate shape, texture and angularity have been developed. NCHRP Report 555, Test Methods for Characterizing Aggregate Shape, Texture, and Angularity, compared different test methods for evaluating aggregate characteristics (Masad et al., 2007[3]).

The Compacted Aggregate Resistance (CAR) Test

Jahn (2004[4]) and others suggest a replacement test called the Compacted Aggregate Resistance test (CAR). This test is similar to a California Bearing Ratio (CBR) test where a piston is placed on a confined sample of fine aggregate and the total piston load is recorded for different penetration depths. The fine aggregate is tested in an “as received” condition, meaning its gradation remains in tact. Therefore, test results not only account for form, angularity and texture, but they also account for fine aggregate gradation.

Video (Figure 30 and Figure 31)

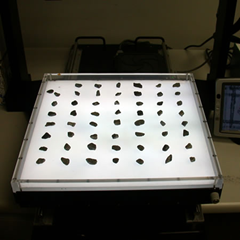

Several research efforts are aimed at using video technology along with digital image processing to more accurately characterize aggregate angularity, surface texture and shape (Masad and Button, 2000[5]; Masad et al., 2000[6]; Fletcher et al., 2003[7]; and Rao et al., 2003[8]). These efforts have proved quite successful, however reliable standard laboratory tests are still under development. It is unknown whether or not the additional expense of digital video and computer processing will prove cost-effective as a replacement for the simpler uncompacted void content test.

Figure 30: Aggregate imaging system.

Figure 30: Aggregate imaging system.

FFigure 31: Close-up of the aggregate imaging system table.

FFigure 31: Close-up of the aggregate imaging system table.

二、 Test Description

The following description is a brief summary of the FAA test,method A. It is not a complete procedure and should not be used to perform the test. The complete FAA test procedure can be found in:

- AASHTO T 304 or ASTM C 1252: Uncompacted Void Content of Fine Aggregate

Summary

A nominal 100 mL calibrated cylindrical measure is filled with fine aggregate of definite grading by allowing the sample to flow through a funnel from a fixed height into the measure. The aggregate is then struck off and its mass is calculated by weighing. The uncompacted void content is calculated using the bulk dry specific gravity of the fine aggregate determined by AASHTO T 84. Uncompacted void content is calculated as the difference between the volume of the cylindrical measure and the absolute volume of the fine aggregate collected in the measure expressed as a percentage of the volume of the measure. This value is also known as the Fine Aggregate Angularity or FAA. Figure 32 shows the typical equipment used.

Figure 32: Fine aggregate angularity test equipment.

Figure 32: Fine aggregate angularity test equipment.

Approximate Test Time

About 1 hour excluding drying time. Fine aggregate drying can take several hours.

Basic Procedure (Method A)

- 1. Obtain an aggregate sample by separating individual sizes from the No. 8 (2.36 mm) sieve to the No. 100 (150 mm) sieve.

- 2. Recombine the individual sizes in the appropriate quantities to meet the specified standard gradation. This results in a 190 g sample.

- 3. Thoroughly mix the sample with a spatula to insure that it is homogeneous.

- 4. Position the jar and funnel section in the stand on a level vibration free surface and center the cylindrical measure under the funnel opening.

- 5. Use a finger to block the opening of the funnel and pour the test sample into the funnel (Figure 33). Level the material in the funnel with the spatula.

- 6. Remove the finger from the opening and allow the sample to fall freely into the cylindrical measure (Figure 34 and Video 6).

- 7. After the funnel empties, strike off excess heaped fine aggregate from the cylindrical measure by a single pass of the spatula with the width of the blade vertical using the straight part of its edge in light contact with the top of the measure (Figure 35 and Video 6). Do not strike-off of the cylinder measure with a sawing motion – the resulting vibration will tend to compact the sample.

- 8. Brush adhering grains away from the lip and base on the outside of the cylinder using a small brush (Video 6). At this point, additional compaction of the material in the cylinder will not affect the test results and will aid in handling.

- 9. Determine the mass of the cylindrical measure and contents. Retain and recombine all materials for the next trial and repeat the test.

- 10. Determine the bulk specific gravity of the fine aggregate. This can be obtained from previous tests or the fine aggregate specific gravity test can be run.

Figure 33: Pouring test sample into funnel.

Figure 33: Pouring test sample into funnel.

Figure 34: Sample falling into the cylindrical measure.

Figure 34: Sample falling into the cylindrical measure.

Figure 35: Striking off the cylinder.

Figure 35: Striking off the cylinder.

Avoid vibration or any disturbance that could cause compaction of the fine aggregate in the cylindrical measure.

三、 Results

Parameters Measured

Uncompacted air voids as a percentage of total volume.

Specifications

A minimum uncompacted void content of 45 percent is generally recommended for the blend of fine aggregate for a high traffic pavement. Many agencies have their own FAA requirements, which can differ from AASHTO M 323 Superpave mix design specifications.

- Table 1: Superpave Mix Design Flat and Elongated Particle Specification

- Table 2: Superpave Mix Design Uncompacted Void Content of Fine Aggregate Specification by Design ESALs

| Material of Concern | Value | Specification | HMA Distress |

|---|---|---|---|

| Fine aggregate | Uncompacted void content | See Table 2 | Deformation, rutting |

| 20-yr ESALs1 (millions) | Depth from Surface | |

|---|---|---|

| ≤ 100 mm (4 inches) | > 100 mm (4 inches) | |

| < 0.3 | – | – |

| 0.3 to < 3 | 40 | 40 |

| 3 to < 10 | 45 | 40 |

| 10 to < 30 | 45 | 40 |

| ≥ 30 | 45 | 45 |

Note 1 Requirements are based on the expected loading in the design lane for a 20-year period regardless of the anticipated design life.

Typical Values

Typical test values range from 38 to 52 percent voids. Crushed materials typically range from 43 to 52 percent voids and natural (uncrushed) sands typically range from 38 to 46 percent voids.

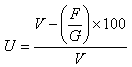

Calculations (Interactive Equation)

Calculate the uncompacted air voids using the following equation:

Where:

U = percent uncompacted air voids

V = volume of the cylindrical measure (ml)

F = sample mass (grams)

G = dry bulk specific gravity of the fine aggregate