Flat and Elongated Particles

一、 Overview

The flat and elongated particle test is used to determine the dimensional ratios for aggregate particles of specific sieve sizes. This characterization is used in the Superpave specification to identify aggregate that may have a tendency to impede compaction or have difficulty meeting VMA specifications due to aggregate degradation. Flat or elongated particles (Figure 36) tend to lock up more readily (rather than reorient) during compaction making compaction more difficult. They also have a tendency to fracture during compaction along their weak, narrow dimension, which can effectively make aggregate gradation finer and possibly cause lower-than-expected VMA.

Figure 36: Flat particles (left) and elongated particles (right).

Figure 36: Flat particles (left) and elongated particles (right).

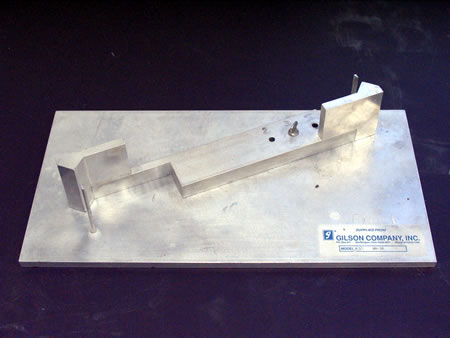

This flat and elongated particle test uses a proportional caliper (Figure 37) to help measure dimensional ratios. The specified ratio is set on the caliper and then about 100 particles are tested for each specified sieve size.

Figure 37: Calipers for the flat and elongated particle test

Figure 37: Calipers for the flat and elongated particle test

The standard flat and elongated particles in coarse aggregate test is:

- ASTM D 4791: Flat Particles, Elongated Particles, or Flat and Elongated Particles in Coarse Aggregates

二、 Background

Flat or elongated aggregate particles can, if present in sufficient number, (1) impede compaction or (2) affect HMA behavior by fracturing during compaction.

Compaction Difficulties

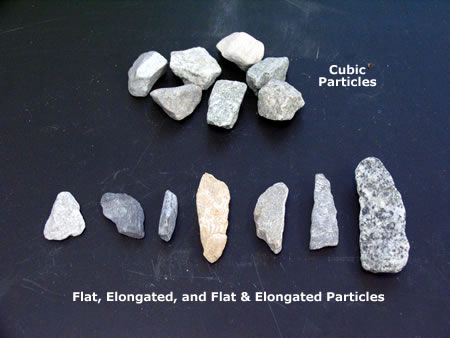

As compared to cubic shaped particles (ones with relatively equal diminsions in all directions) flat or elongated particles tend to impede compaction. These particles tend to lock up with adjacent aggregate particles more readily than cubic particles and resist reorientation into a more dense configuration. Therefore, significant numbers of flat or elongated particles can increase the compactive effort required to achieve a given density for a given HMA mixture. In other words, flat and elongated particles make HMA compaction more difficult.

Effect on HMA Behavior

Flat or elongated particles also have a tendancy to fracture along their weak, narrow dimension when subjected to compaction loading. If they are present in large enough quantity, this fracturing can effectively change the aggregate gradation as larger flat and elongated particles are broken into smaller, more cubic particles (Figure 38). The resulting greater number of fine particles will fill existing void spaces and reduce the VMA. This reduction in VMA can result in too little room available for the asphalt binder to coat the aggregate particles, which can result in mixture instability (rutting and shoving). Also, the resulting lower VMA may make the HMA mixture highly sensitive to small variations in asphalt binder content. Thus, a small increase in asphalt binder content associated with typical manufacturing tolerances that would normally be absorbed in an HMA with adequate VMA, may result in low stability in a low VMA mixture. Also, the fracturing of flat and elongated particles within the HMA will create aggregate faces that are uncoated with asphalt binder, which can increase durability problems.

Figure 38: Cubical particles (top) seen next to flat, elongated and flat &

elongated particles (below).

Figure 38: Cubical particles (top) seen next to flat, elongated and flat &

elongated particles (below).

Typical Definition

The dimensional ratio at which an aggregate particle is considered too flat or too elongated can vary from specification to specification. Typical ratios are 2:1, 3:1, 4:1 and 5:1 (Figure 39). Superpave mix design specifies a ratio of 5:1 and tests particles for flatness and elongation. Other agencies have used different ratios.

Figure 39: Range of flat and elongated particle ratios. The 5:1 particle is

very flat, giving a length:height ration of 5:1. The height:width dimensions seen in the

photo are about 4:1.

Figure 39: Range of flat and elongated particle ratios. The 5:1 particle is

very flat, giving a length:height ration of 5:1. The height:width dimensions seen in the

photo are about 4:1.

三、 Test Description

The following description is a brief summary of the test. It is not a complete procedure and should not be used to perform the test. The complete flat and elongated particle test procedure can be found in:

- ASTM D 4791: Flat Particles, Elongated Particles, or Flat and Elongated Particles in Coarse Aggregates

Summary

Individual aggregate particles of specific sieve sizes are tested for ratios of width to thickness, length to width, or length to thickness. The test is performed on a sample of coarse aggregate reduced from a representative field sample. The sample is sieved to separate each size larger than the 0.375 inch (9.5 mm) sieve. Each size is then tested in a proportional caliper device (Figure 40). Particles are weighed or counted to determine a percentage of flat, elongated, or flat and elongated particles in a sample.

Figure 40: Flat and elongated particle test equipment.

Figure 40: Flat and elongated particle test equipment.

Approximate Test Time

30 minutes.

If particle mass rather than particle count is to be used, sample preparation will take at least 12 hours or overnight because the aggregate needs to be oven dry before it is weighed to ensure accuracy.

Basic Procedure

- 1. Sieve a sample of coarse aggregate and collect those particles retained on the specified sieve size(s); usually the 0.375 inch (9.5 mm) or No. 4 (4.75 mm) sieve are specified. Reduce each specified size fraction until approximately 100 particles are obtained for each specified size fraction.

- 2. Checking for flatness OR elongation. Test each of the particles in each of the size fractions and place them into one of three groups: flat, elongated, or neither flat nor elongated.

- Testing for flatness (Figure 41). Set the larger opening of the proportional caliper equal to the particle width. The particle is flat if the thickness fits in the smaller opening.

- Testing for elongation (Figure 42). Set the larger opening of the proportional caliper equal to the particle length. The particle is elongated if the width fits in the smaller opening.

- After all particles are tested, determine the proportion of the sample in each group by either count or mass.

- 3. Checking for flatness AND elongation (Video 1). Use the proportional caliper device to check flat and elongation of the particles.

- Set the larger opening of the caliper equal to the length of the particle. The particle is considered flat and elongated if the particle, when oriented to measure its thickness, can pass completely through the smaller opening of the caliper.

- After all particles are tested, determine the proportion of the sample in each group by either count or mass.

Figure 41: Testing for flatness.

Figure 41: Testing for flatness.

Figure 42: Testing for elongation.

Figure 42: Testing for elongation.

四、 Results

Parameters Measured

Percentage or coarse aggregate particles of a specified size or sizes that are considered flat, elongated or flat and elongated according to a specified ratio.

Specifications

A maximum percentage of flat and elongated particles is usually specified. The actual definition of flat, elongated and flat and elongated varies from specification to specification but is typically a dimensional ratio of 3:1, 4:1 or 5:1.

- Table 3: Superpave Mix Design Flat and Elongated Particle Specificatio

- Table 4: Superpave Mix Design Flat and Elongated Particle Specification by Design ESALs

| Material of Concern | Value | Specification | HMA Distress |

|---|---|---|---|

| Coarse Aggregate | Flat & elongated particle fraction | See Table 2 | Compaction, instability, rutting |

Note 1 The Superpave mix design specification uses a 5:1 dimensional ratio for determining flat and elongated particles.

| 20-yr ESALs1 (millions) | Maximum Flat & Elongated (%) |

|---|---|

| < 0.3 | – |

| 0.3 to < 3 | 10 |

| 3 to < 10 | 10 |

| 10 to < 30 | 10 |

| ≥ 30 | 10 |

Note 1 Requirements are based on the expected loading in the design lane for a 20-year period regardless of the anticipated design life.

Typical Values

Values can vary widely depending upon aggregate source and crushing method.

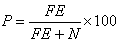

Calculations (see Interactive Equation)

Calculate the percentage of flat, elongated or flat and elongated particles for each specified sieve size using the following equation.

Where:

- P = percentage of particles classified as flat, elongated or flat and elongated

- FE = mass or count of particles that are flat, elongated or flat and elongated

- N = mass or count of particles that are neither flat, elongated or flat and elongated

The weighted average of the different sieve sizes can be reported by weighting the percentage of flat, elongated or flat and elongated particles for each sieve size by the actual proportion of each sieve size in the sample being tested.