Pressure Aging Vessel

一、 Overview

The Pressure Aging Vessel (PAV) (Figure 193) provides simulated long term aged asphalt binder for physical property testing. Asphalt binder is exposed to heat and pressure to simulate in-service aging over a 7 to 10 year period.

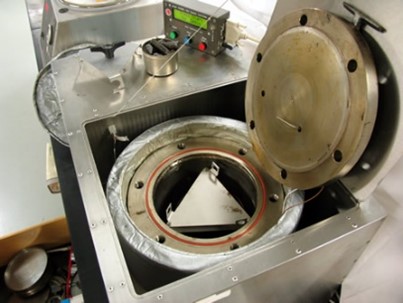

Figure 193: Pressure Aging Vessel (PAV)

Figure 193: Pressure Aging Vessel (PAV)

The basic PAV procedure takes RTFO aged asphalt binder samples, places them in stainless steel pans and then ages them for 20 hours in a heated vessel pressurized to 305 psi (2.10 MPa or 20.7 atmospheres). Samples are then stored for use in physical property tests.

The standard Pressure Aging Vessel procedure is found in:

- AASHTO R 28: Accelerated Aging of Asphalt Binder Using a Pressurized Aging Vessel (PAV)

二、 Background

Many HMA distresses either initiate or become more severe in older pavements. Therefore, a method to simulate aged asphalt binder is important in investigating and predicting these types of distresses. The Superpave PG binder specification calls for long term aged asphalt binder to be tested at intermediate and cold temperatures to determine fatigue and low temperature cracking (Figure 194) resistance.

Figure 194: Low temperature cracking (left) and fatigue cracking

(right).

Figure 194: Low temperature cracking (left) and fatigue cracking

(right).

Asphalt Binder aging by Oxidation

Although many different factors contribute to asphalt binder aging, the key component of concern for the PAV is oxidation. Oxidation increases an asphalt’s viscosity with age up until a point when the asphalt is able to quench (or halt) oxidation through immobilization of the most chemically reactive elements.

Oxidation Occurrence

Oxidation can occur in the field during two distinct stages of a pavement’s life (Bahia and Anderson, 1995[1]):

- Oven tests. These are older than pressure tests and are relatively simple and quick. They rely on high temperatures and thin asphalt films to accelerate the oxidation process. However, during this aging process, asphalt binder samples lost a significant amount of volatiles as well. Field tests showed that the constituent asphalt binder in older in-service HMA did not lose significant amounts of volatiles after placement.

- Pressure tests. This approach, although originally less popular than oven tests, has been around for over 40 years. Pressure tests work by using high pressure to increase the diffusion rate of oxygen into an asphalt binder sample. In general, this approach limits the loss of volatiles while aging the asphalt binder sample.

- Volatile loss is minimized.

- Aging can be accomplished without high temperatures.

- Large enough sample sizes can be accommodated.

- Field climate conditions can be approximated.

- Laboratory use is practical.

Based on the preceding descriptions, a pressure test was desired for simulating long term asphalt binder aging because (Bahia and Anderson, 1995[1]):

The standard asphalt binder PAV was developed at Iowa State University for long term aging of asphalt cements and is also a standard method for aging rubber products (as in ASTM D 454 and ASTM D 572) (Roberts et al., 1996[2]).

Reasons for PAV Time and Temperature (from Bahia and Anderson, 1995[1])

The PAV process is typically conducted for 20 hours at either 194, 212 or 230°F (90, 100 or 110°C). These were chosen for practical, rather than theoretical reasons.

Original PAV experiments were conducted at 300 psi (2.07 MPa) and 60°C for 6 days. Results showed insufficient aging and the test period was deemed too long. Therefore, in order to increasing the aging rate (producing a shorter test) the test temperature was raised. Originally, a test temperature of 212°F (100°C) was chosen but, during field validation, it was found to be overly harsh for cold climates and too mild for hot climates. Therefore, three elevated temperatures are used, each one to simulate a different general environmental condition:

| Temperature | Simulation |

|---|---|

| 194°F (90°C) | cold climate |

| 212°F (100°C) | moderate climate |

| 230°F (110°C) | hot climate |

Currently, there is discussion about these temperatures, how they relate to field performance, and whether they should be changed or at least simplified.

The PAV time of 20 hours was selected because it was thought that this time would allow for one test plus the removal of completed samples and insertion of new samples within a 1 day window.

三、 Test Description

The following description is a brief summary of the test. It is not a complete procedure and should not be used to perform the test. The complete procedure can be found in:

- AASHTO R 28: Accelerated Aging of Asphalt Binder Using a Pressurized Aging Vessel (PAV)

Summary

RTFO aged asphalt binder is placed in an unpressurized PAV preheated to the test temperature. When the PAV nears the test temperature it is pressurized to 300 psi (2.07 MPa). After 20 hours of treatment the samples are removed, degassed and stored for future testing. Figure 197 shows the major PAV equipment.

Figure 197: Major PAV equipment.

Figure 197: Major PAV equipment.

Approximate Test Time

22 hours from sample preparation to end of vacuum degassing procedure.

Basic Procedure

- 1. Heat RTFO aged asphalt binder until fluid enough to pour. Stir sample and pour 50 g into a preheated thin film oven pan (Video 1). Pour as many pans as needed for intermediate and cold temperature testing (usually 1 – 3 pans will suffice).

- 2. Place pans (Figure 198) in a pan holder (Figure 199) and place inside preheated PAV (Figure 200). Video 23 shows this process.

- 3. Seal the PAV and allow it to return to the aging temperature.

- Aging temperature is based on the climate where the material is expected to be used. For climates where a PG 52 or lower is specified, the PAV is performed at 194°F (90°C). For climates where a PG 58 or higher is specified, the PAV is performed at 212°F (100°C). For desert climates, it is recommended to perform the PAV at 230°F (110°C).

- 4. Once the PAV has reached the desired temperature, pressurize the PAV to 300 psi (2.07 MPa) and maintained the pressure for for 20 hours.

- 5. At the end of the aging period, gradually release the pressure and remove the pans from the PAV.

- 6. Place the pans in an oven set at 325°F (163°C) for 15 minutes, then scrape into a single container sized so that the depth of the residue in the container is between 0.55 and 1.57 inches (14 and 40 mm).

- 7. Place the container in a vacuum oven (Figure 201) at 338°F (170°C) and degas the sample for 30 minutes to remove entrapped air. If not degassed, entrapped air bubbles may cause premature breaking in the DTT test.

Heating time should be minimized to avoid oxidative hardening and volatile loss. (AASHTO, 2000c).

Figure 198: PAV pan (with a quarter for scale).

Figure 198: PAV pan (with a quarter for scale).

Figure 199: Pan holder with one PAV sample inserted.

Figure 199: Pan holder with one PAV sample inserted.

Figure 200: PAV viewed from the top with the pan holder

inserted.

Figure 200: PAV viewed from the top with the pan holder

inserted.

Returning the PAV to aging temperature must be done within 2 hours for the procedure to remain valid (AASHTO, 2000c).

Figure 201: Vacuum oven.

Figure 201: Vacuum oven.

四、 Results

Parameters Measured

None. The PAV is used to simulate asphalt binder aging for use in other tests associated with performance graded asphalt binder.

Specifications

None.

Typical Values

None.

Calculations

None.