Binder Tests

Ductility

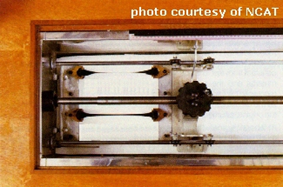

The ductility test (Figure 162) measures asphalt binder ductility by stretching a standard-sized briquette of asphalt binder (Figure 163) to its breaking point. The stretched distance in centimeters at breaking is then reported as ductility. Like the penetration test, this test has limited use since it is empirical and conducted at only one temperature (25° C (77° F)).

read more ...Thin-Film Oven

The thin-film oven (TFO) test simulates short-term aging by heating a film of asphalt binder in an oven for 5 hours at 163° C (325° F). The effects of heat and air are determined from changes incurred in physical properties measured before and after the oven treatment by other test procedures.

read more ...Asphalt Binder and Characterization

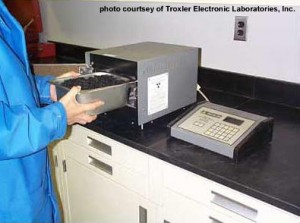

The asphalt content and gradation test can be used for HMA quality control, acceptance testing or forensic analysis. The three major test methods, solvent extraction, nuclear asphalt content gauge and ignition furnace are discussed here. Each method offers a way to determine asphalt content and aggregate gradation from an HMA sample.

read more ...Bending Beam Rheometer

Overview The Bending Beam Rheometer (BBR) test (see Figure 168) provides a measure of low temperature stiffness and relaxation properties of asphalt binders. These parameters give an indication of an asphalt binder’s ability to resist low temperature cracking. The BBR is used in combination with the DTT to determine an asphalt binder’s low temperature PG grade. As with other Superpave binder tests, the actual temperatures anticipated in the area where the asphalt binder will be placed determine the test temperatures used.

read more ...Direct Tension Tester

Overview The Direct Tension Tester (DTT) test (see Figure 177, Figure 178) provides a measure of low temperature stiffness and relaxation properties of asphalt binders. These parameters give an indication of an asphalt binder’s ability to resist low temperature cracking. The DTT is used in combination with the BBR to determine an asphalt binder’s low temperature PG grade determination. As with other Superpave binder tests, the actual temperatures anticipated in the area where the asphalt binder will be placed determine the test temperatures used.

read more ...Dynamic Shear Rheometer

Overview The dynamic shear rheometer (DSR) (Figure 1 and Figure 185) is used to characterize the viscous and elastic behavior of asphalt binders at medium to high temperatures. This characterization is used in the Superpave PG asphalt binder specification. As with other Superpave binder tests, the actual temperatures anticipated in the area where the asphalt binder will be placed determine the test temperatures used.

read more ...Penetration Test

Aside from chewing, the penetration test is the oldest asphalt test. In 1888, H.C. Bowen of the Barber Asphalt Paving Company invented the forerunner to the penetration test, the Bowen Penetration Machine (Halstead and Welborn, 1974[1]). It’s basic principle, and the basic principle of the penetration test, was to determine the depth to which a truncated No. 2 sewing needle penetrated an asphalt sample under specified conditions of load, time and temperature. In 1915, ASTM even went as far as specifying the brand of needle (R.J. Roberts Parabola Sharps No. 2) (Halstead and Welborn, 1974[1]).

read more ...Pressure Aging Vessel

Overview The Pressure Aging Vessel (PAV) (Figure 193) provides simulated long term aged asphalt binder for physical property testing. Asphalt binder is exposed to heat and pressure to simulate in-service aging over a 7 to 10 year period.

read more ...Rolling Thin-Film Oven

Overview The Rolling Thin-Film Oven (RTFO) procedure (Figure 202) provides simulated short term aged asphalt binder for physical property testing. Asphalt binder is exposed to elevated temperatures to simulate manufacturing and placement aging. The RTFO also provides a quantitative measure of the volatiles lost during the aging process.

read more ...Rotational Viscometer

Overview The Rotational Viscometer (RV) (Figure 207 and Figure 2) is used to determine the viscosity of asphalt binders in the high temperature range of manufacturing and construction. This measurement is used in the Superpave PG asphalt binder specification. The RV test can be conducted at various temperatures, but since manufacturing and construction temperatures are fairly similar regardless of the environment, the test for Superpave PG asphalt binder specification is always conducted at 275°F (135°C).

read more ...Softening Point

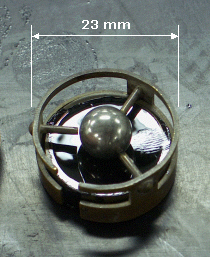

Softening Point The softening point is defined as the temperature at which a bitumen sample can no longer support the weight of a 3.5-g steel ball. Although it is commonly used in Europe, it is mostly used for roofing asphalts in the U.S. Basically, two horizontal disks of bitumen, cast in shouldered brass rings (Figure 213), are heated at a controlled rate in a liquid bath while each supports a steel ball. The softening point is reported as the mean of the temperatures at which the two disks soften enough to allow each ball, enveloped in bitumen, to fall a distance of 25 mm (1.0 inch) (AASHTO, 2000[1]).

read more ...Spot Test

The spot test is used to determine whether or not an asphalt cement has been damaged during processing due to overheating. This damage, called “cracking”, occurs because the actual molecules are thermally broken apart. Cracked asphalt cements tend to be less ductile and more susceptible to aging effects. Since modern refining practices rarely cause cracking, the spot test is not often specified.

read more ...