Rolling Thin-Film Oven

一、 Overview

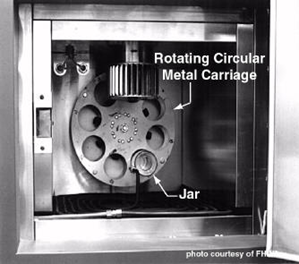

The Rolling Thin-Film Oven (RTFO) procedure (Figure 202) provides simulated short term aged asphalt binder for physical property testing. Asphalt binder is exposed to elevated temperatures to simulate manufacturing and placement aging. The RTFO also provides a quantitative measure of the volatiles lost during the aging process.

Figure 202: Rolling thin-film oven test.

Figure 202: Rolling thin-film oven test.

The basic RTFO procedure takes unaged asphalt binder samples in cylindrical glass bottles and places these bottles in a rotating carriage within an oven. The carriage rotates within the oven while the 325°F (163°C) temperature ages the samples for 85 minutes. Samples are then stored for use in physical properties tests or the PAV.

The standard Rolling Thin-Film Oven test is:

- AASHTO T 240 and ASTM D 2872. Effect of Heat and Air on a Moving Film of Asphalt (Rolling Thin-Film Oven Test)

二、 Background

One of the basic tenets of the Superpave PG binder specification is that tests should be as closely tied with field performance as possible. Seeing as the constituent asphalt binder in HMA undergoes significant aging during the manufacturing and placement processes (Figure 203), a method to simulate the aging is important in investigating and predicting early age HMA pavement behavior and distresses. Specifically, the Superpave PG binder specification calls for short term aged asphalt binder to be tested at high temperatures to determine fatigue and rut resistance.

Figure 203: HMA placement.

Figure 203: HMA placement.

Asphalt Binder aging by Loss of Volatiles

Although many different factors contribute to asphalt binder aging, the key component of concern for the RTFO is the loss of volatiles. The loss of smaller molecules from the asphalt binder, often termed “volatiles” increases an asphalt’s viscosity.

Loss of Volatiles Occurrence

Asphalt binders typically lose volatiles during the manufacturing and placemen processes. The elevated temperature of these processes ages the asphalt binder by driving off a substantial amount of volatiles. Field tests have shown that in-place asphalt binder does not lose a significant amount of volatiles over its life (Corbett and Merz, 1975[1]).

Aging Simulation

The RTFO aging procedure is used to simulate aging during mixing and placement, while the PAV aging procedure is used to simulate aging during in-service life. Therefore, asphalt binder tests concerned with mix and placement properties (such as the DSR) are conducted on RTFO aged samples, while asphalt binder tests concerned with in-service performance (such as the DSR, BBR and DTT) are performed on samples first aged in the RTFO and then in the PAV.

RTFO Aging of Modified Asphalt Binders

The RTFO has problems with highly viscous binders (e.g., some polymer modified asphalt binders and PG 70-XX and higher) because they do not flow properly in the bottles as they are rotated.

Test Origins

The RTFO was developed as an improvement to the Thin-Film Oven Test (TFOT) for short term asphalt binder aging. The TFOT placed asphalt binder samples in shallow pans (of the same dimensions as those used for the PAV) and then heated them in an oven for an extended period of time to accomplish simulated aging. The RTFO is an improvement over the TFOT because:

- Fresh asphalt binder is continuously exposed to heat and air flow due to the rolling action of the carousel ( Video 1).

- Asphalt binder modifiers, if used, usually remain dispersed in the asphalt binder due to the rolling action of the carousel (Figure 204).

- No surface skin, which inhibits aging, forms on the asphalt binder because of the rolling action of the carousel.

- The test is reasonably short at 85 minutes.

Figure 204: RTFO bottles. The bottle at left is after the RTFO test,

the bottle in the middle is before the test.

Figure 204: RTFO bottles. The bottle at left is after the RTFO test,

the bottle in the middle is before the test.

三、 Test Description

The following description is a brief summary of the test. It is not a complete procedure and should not be used to perform the test. The complete procedure can be found in:

- AASHTO T 240 and ASTM D 2872: Effect of Heat and Air on a Moving Film of Asphalt (Rolling Thin-Film Oven Test)

Summary

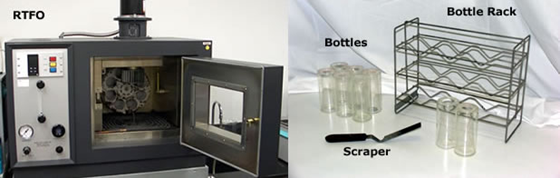

Unaged asphalt binder is placed in a cylindrical jar, which is then placed in a carousel inside a specially designed oven. The oven is heated to 325°F (163°C) and the carrousel is rotated at 15 RPM for 85 minutes. The carousel rotation continuously exposes new asphalt binder to the heat and air flow and slowly mixes each sample. Figure 205 shows major RTFO equipment.

Figure 205: RTFO equipment.

Figure 205: RTFO equipment.

Approximate Test Time

3 hours from sample preparation to scraping of final bottle.

Basic Procedure

- 1. Heat a sample of asphalt binder until it is fluid to pour. Stir sample to ensure homogeneity and remove air bubbles.

- 2. If a determination of mass change is desired, label two RTFO bottles and weigh them empty. These are designated as the “mass change” bottles. Record the weights.

- 3. Pour 1.23 oz (35 g) of asphalt binder into each bottle (Figure 206). Immediately after pouring each bottle, turn the bottles on their side without rotating or twisting and place them on a cooling rack.

- 4. Allow all bottles to cool 60 to 180 minutes.

- 5. After cooling, weigh the two mass change bottles again. Record the weights.

- 6. Place the bottles in the RTFO oven carousel (Video 25), close the door, and rotate carousel at 15 RPM for 85 minutes . During this time, maintain the oven temperature at 325°F (163°C) and the airflow into the bottles at 244 in3/min (4000 ml/min).

- 1. Remove the bottles one at a time from the carousel, setting the mass change bottles aside. Residue from the remaining bottles should be transferred to a single container. Remove residue from each bottle by first pouring as much material as possible, then scraping the sides of the bottle to remove any remaining residue (Video 26). There is no standard scraping utensil but at least 90 percent of the asphalt binder should be removed from the bottle. RTFO residue should be tested within 72 hours of aging.

- 1. After cooling the two mass change bottles for 60 – 180 minutes, weigh them and discard their residue. Record the weights.

Figure 206: Pouring hot asphalt binder into the RTFO bottle

Figure 206: Pouring hot asphalt binder into the RTFO bottle

Any scraping tool may be used but an average of 90% of the residue must be removed from the sample bottles. It has been found that circumferential scraping is usually more effective than lengthwise scraping.

一、 Results

Parameters Measured

Mass change of a sample as a percent of initial mass.

The RTFO is primarily used to simulate short term asphalt binder aging for use in other tests.

Specification

Table 19: Performance Graded Asphalt Binder RTFO Specification

| Material | Value | Specification | Property of Concern |

|---|---|---|---|

| Unaged binder | Mass loss1 | ≤ 1.0% | None |

Note 1

Although some samples can gain weight due to the oxidative products formed during the test (Roberts et al., 1996[2]), there is currently no limit on mass gain.

Typical Values

Typical mass loss is in the range of 0.05 to 0.5 percent.

Calculations

Calculations can be done for the mass change bottles in the following form:

Where:

- Wbi = bottle + binder weight before aging

- Wbf = bottle + binder weight after aging

- Wo = empty bottle weight

- A = initial sample weight

- B = final sample weight